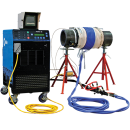

Miller Big Blue 800X Duo Air Pak

Get the advantage and reduce costs with the Big Blue 800X Duo Air Pak!

The 800X is a 3 phase engine driven machine which features two independent arcs, with up to 400 Amps each, meaning 2 operators can work off one power source. As a result, a fleet of engine drive machines can be reduced, resulting in lower capital investment.

The 800X machine also reduces costs associated with engine servicing, fuel, compressor servicing and compliance testing, saving you money annually. With more arcs and better fuel economy the 800X also increases profits, with an estimated savings of 34% compared with single operator units. Overall the 800X can save you money in more ways than one!

Better than ever the 800X has serious power with 800 Amps of weld output, plus 27,000 watts of three phase 415 V power* and 5,500 watts of single phase, 240V power**.

The 800X also comes fitted with vandal proof doors for extra security, and has a duetz turbocharged engine which consumes less. In addition, the 800X features infinite arc control, which allows the user to change the arc characteristics for specific applications in Stick, MIG and FCAW.

A special feature of the 800X is the Ingersoll rang compressor. Ultra-reliable this rotary screw compressor has a life expectancy of 30,000 hours resulting in longer servicing intervals. And we won’t forget to mention the electronic engine display, which simultaneously displays fuel level, engine hours, coolant temperature, oil pressure, battery volts, engine RPM, air pressure, compressor hours and engine diagnostics for quick and easy servicing. Seriously impressive!

The Big Blue 800X Duo Air Pak is a complete mobile welding air and power workshop for onsite maintenance and fabrication.

Check out the 800X product page for further information

Click here to see just how you can save 6 ways with the 800X!

For more information, contact our customer support team on 1300 300 884.

* Dependent of weld output.

** Independent of weld output.