- MR301456

The simple interface on the feeder allows operators to adjust parameters at the point of use with no control cords.

Impact-resistent case and the elimination of feeder control cords provides a solid solution to last in harsh environments.

Simply connect the ArcReach SuitCase feeder to your weld lead and you are ready to go. The power source automatically switches settings to run conventional wire processes.

Add the flux-cored capability of the XMT 350 FieldPro for fill and cap passes for increased productivity.

ArcReach feeders and remotes have been extensively field proven and deliver the performance you need with ruggedly constructed internal components.

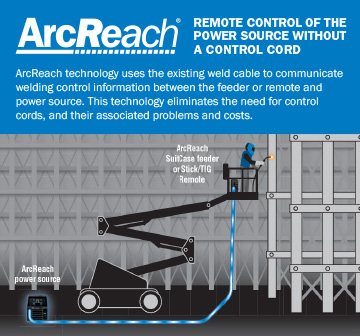

The chances of slip, trip or fall injuries are decreased because ArcReach technology allows welding operators to make parameter changes at the wire feeder/ remote instead of having to travel through multi-story and cluttered jobsites back to the power source.

ArcReach capabilities eliminate the time spent tracing weld cables hundreds of feet back to the power source because weld operators can make adjustments at the ArcReach wire feeder or remote.

Ensures that the voltage a weld operator sets is the voltage they get by automatically adjusting voltage based on weld cable length, even hundreds of feet away from the power source.

* Only available when connected to an XMT 350 FieldPro power source.

Maximise fleet compatibility and get the benefits of ArcReach when you pair XMT 350 FieldPro welders and ArcReach feeders with other ArcReach compatible products.

Heavy-duty drive motor with tachometer control provides wire feed speed that is accurate and consistent from the start of the weld to the finish and from one weld to the next, which provides consistent arc quality. Wide voltage range for small and large wires with no contactor chatter or arc outages.

More control for weld operators with quick, easy adjustments at the wire feeder / remote.

Change weld parameters while the arc is on.

* Only available when connected to an XMT 350 FieldPro power source.

Make loading the wire easy and do not deform the wire on the way into the drive rolls. Simply thread the wire through the pins and into drive rolls. There are two ways to advance the wire through the drive roll and into the gun. Either open the pressure arm and thread the wire into the grooves in the drive roll and on into the gun inlet or place the wire between the pins and use the jog/ purge switch to advance the wire through the drive roll.

Provides easy adjustment and consistent pressure on the drive rolls and wire.

Works with guns having corresponding locking grooves to prevent gun from being pulled out if the feeder is dragged by the gun.

For the harshest environments adds exceptional reliability. Board has full-trigger isolation so a shorted gun trigger will not affect feeder operation.

Recessed into back of case is protected from incidental contact by the weld cable, ensuring consistent and contaminant-free shielding gas delivery to the gun

Specifically designed for mobile welding applications to provide smooth and consistent wire delivery. Improved motor torque and drive roll system are designed to feed small diameter solid wire (.023 inch) to large-diameter cored wire (5/64 inch).

Ensures wire feed speed accuracy and consistency that rivals the best bench top feeders—making it easier to produce quality welds.

Technology can display voltage and wire speed, and also amperage if desired. Meters can be seen clearly even in direct sunlight.

With the ability to open the door to change wire with feeder in vertical position.

Helps keep dirt from clogging and affecting gas flow.

| Input Power | Input Welding Circuit Rating | Wire Speed | Electrode Wire Diameter Capacity | Max. Spool Size Capacity | Dimensions (mm) | Weight |

|---|---|---|---|---|---|---|

| Operates on open-circuit voltage and arc voltage: 14 - 48 VDC/110 max. OCV | 425 A at 60% Duty Cycle | 1.3 - 19.8 m/ min dependent on arc voltage | Solid Wire: 0.6 - 1.4mm Flux Cored: 0.8 - 2.0mm | 305mm diameter up to 20kg | H: 394 W: 229 D: 533 | 15.9 kg |