With tough rural conditions, Julian from Smith’s Excavations and Earth Moving, needed a welder to be light, mobile and easy to maintain while remaining rugged and durable to suit the surroundings of remote New South Wales.

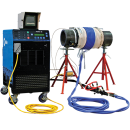

Through consultation with WIA’s Glenn Callinan, Julian found a solution to fit his business in the Miller Bobcat 250 (Petrol), paired with the Miller SuitCase® X-Treme 12VS wirefeeder and Bernard Ironmate™ gaseless MIG gun.

Offering welding repairs and modifications on irrigation pipe lines that service the cotton industry is tough business said Julian. Conditions in summer can reach over 50 degrees Celsius and drop below zero on cold winter mornings.

When Julian Smith from Moree decided to invest in new mobile welding plant he knew that he required a machine that was simple to set up, reliable, gave a great welding arc and tough enough to handle the conditions we find in remote North West NSW.

The answer was the Miller Bobcat 250 Petrol Package including the Miller SuitCase® 12 voltage sensing wirefeeder and Bernard Ironmate™ gasless MIG gun.

The compact design 250 amp welding power @100% Duty cycle, reliable Kohler Petrol Engine, user friendly control panel and 10 kva generator power gives Julian everything he requires to get the job done.

Julian says ‘The addition of the SuitCase® voltage sensing feeder and gasless MIG gun paired with the Hobart Fabshield 21B 1.6mm shelf-shielded MIG wire allows increased productivity over stick welding and gets me home earlier.’ ‘I wanted a quality solution that would live up to the tough conditions on the job, while increasing productivity and WIA delivered’ Mr Smith finished.

Related Products