PAPRs - What are they all about?

Powered air purifier respirators (PAPR) protect your respiratory system by removing fumes, dusts and mists, as well as a combination of contaminants from the air. PAPR systems include battery-powered technology that purifies the air for long periods of time – making it a great choice for welders seeking enhanced protection when welding for extended periods of time.

The differences between a PAPR system and a traditional welding helmet:

Whether a welder is familiar with the use of a traditional welding helmet or open to exploring alternative options, there are variations associated with each choice of personal protection a welder may like to consider.

| Aspect | PAPR Helmet | Traditional Welding Helmet |

|---|---|---|

| Eye Protection |

Provides eye protection |

Provides eye protection |

| Respiratory Protection |

Offers high level of respiratory protection |

Does not offer respiratory protection. Alternatively, operators have the choice to utilise a disposable or half-face tight-fitting respirator. This option is suitable in scenarios where the exposure to airborne contaminants is minimal, and the hazardous levels of such contaminants are low. |

| Comfort Level |

Offers continuous filtered air cooling, enhancing comfort during prolonged welding sessions. Delivers a refreshing breeze across the face and head, particularly beneficial in warm conditions. PAPRs can accommodate certain amounts of facial hair. |

Lacks air cooling functionality. The use of disposable or half-face respirators may impede breathing, particularly during extended periods of use. Fit testing is required, as not all brands and types can fit every face. Operators are required to have a clean-shaven face. |

| Grinding Shield |

Flip up helmet comes with an in-built grind shield. |

Most traditional helmets do not flip up or come with an integrated grind shield. |

| Flexibility | Filters are replaceable | Disposable filters are not replaceable |

| Cost | Provides advanced welding protection features for added value | More budget-friendly option |

Something to consider

The level and quantity of welded fumes generated can vary significantly across different welding processes. To determine the most suitable option, it is important to have a comprehensive understanding of the specific types of weld fumes being produced.

Not all welding processes produce the same level and amount of welded fumes. To ensure best option you must understand what types of weld fumes are being produced. As seen in the above table, PAPR systems offer superior comfort and protection levels as well as reduce the risk of operators breathing in harmful fumes whilst welding. For those operators who weld for long periods of time, choosing a PAPR system will offer greater respiratory protection compared to traditional welding helmets.

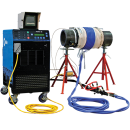

Miller Vortex HDV PAPR System

With a variety of different PAPR systems on the market, it can be confusing knowing which type of welding helmet to purchase. Miller’s Vortex HDV PAPR System is equipped with a lightweight belt-mounted blower assembly and provides an elevated level of respiratory protection for welding activities – enhancing comfort and safety, particularly during extended periods of work.

Key features and benefits:

Cooling, comfort and protection:

- 6 air points and 3 air speeds to maximise operator cooling and comfort.

- Lightweight blower unit. Only 1362g. Provides more comfort while welding and extends wearability.

- Includes 2x lithium-ion batteries. One for usage and one for charging.

- Integrated 3-point backpack style shoulder straps. Reduces fatigue over long shifts.

- Filter timer to track how many hours of use the filter has. Prevents filter overuse.

- Maximises protection.

Visibility:

- Exclusive Miller HDV technology: Provides a sharp detailed view with minimal distortion.

- Exclusive Miller ClearLight 2.0 Technology: Provides a clearer, brighter more realistic view.

- Exclusive Miller X-Mode Technology. The lens only darkens when you start to weld. Idea for outdoor, low amp TIG and out of position welding.

Ultra HDV Auto-Darkening Welding Helmet

Not looking in to a PAPR system quite yet? Miller’s Ultra HDV Auto-Darkening Welding Helmet is packed with all the desirable features a welder may need.

Key features and benefits:

- Suitable not only for MIG/STICK/TIG welding, but for plasma cutting/welding and gouging.

- Half shade adjustment for more precise lens adjustment.

- The HDV lens technology offers clear visibility with minimal distortion, while ClearLight 2.0 technology optimises the light spectrum for a clearer view.

- Features a large grind shield, a bright 2.5 light state for grinding, and comfortable padding that conforms to the user's head shape.

- Exclusive Miller HDV technology: Provides a sharp detailed view with minimal distortion.

- Exclusive Miller ClearLight 2.0 Technology: Provides a clearer, brighter more realistic view.

- Exclusive Miller X-Mode Technology. The lens only darkens when you start to weld. Idea for outdoor, low amp TIG and out of position welding.

- Exlusive Miller InfoTrack 2.0 technology allows users to store settings and track weld time and arc counts, and X-Mode technology allows the lens to darken when an arc strikes only, making it ideal for welding outdoors, low amp TIG and out of position welding.

Traditional welding helmet or PAPR? The choice is yours!

In the end, the choice to invest in either a traditional welding helmet or a PAPR system rests with the welder and their individual requirements. Drawing on years of expertise in innovative welding solutions, Miller is committed to maintaining the highest standards for both PAPR systems and traditional welding helmets, prioritising the well-being and safety of every user.