ARC & TIG Welders

-

Weldarc 135NEW

-

Weldarc 145NEW

-

Weldarc 185NEW

-

Weldarc 200DCNEW

-

Weldarc 200AC/DCNEW

-

Maxstar 210DX

-

Maxstar 400

-

Dynasty 210NEW

-

Dynasty 300NEW

-

Dynasty 400

Selection Chart

| Product | Process | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stick | AC TIG | DC TIG | High Freq | Lift Arc | Pulse | Low OCV | VRD | Weldable Materials |

Welding Amp. Range |

Input Voltage | Generator Power Required | Typical Applications | |

| Weldarc 135 |

|

|

Steel, Stainless Stee, Cast Iron |

135 A @ 25.4 V, 20% Duty Cycle

60 A @ 22.4 V, 100% Duty Cycle |

240V |

7 kVA | Repair and Maintenance, Farming, DIY Projects | ||||||

| Weldarc 145 |

|

|

|

|

Steel, Stainless Steel, Cast Iron |

145 A @ 25.8 V, 20% Duty Cycle

56 A @ 22.2 V, 100% Duty Cycle |

240V |

7 kVA | Light Fabrication, Repair and Maintenance, Farming, Building and Construction | ||||

| Weldarc 185 |

|

|

|

|

Steel, Stainless Steel, Cast Iron |

185 A @ 27.4 V, 25% Duty Cycle 92 A @ 23.7 V, 100% Duty Cycle |

240V |

8 kVA | Light Fabrication, Repair and Maintenance, Farming, Building and Construction | ||||

| Weldarc 200DC |

|

|

|

|

|

|

Steel, Stainless Steel, Copper |

200 A at 18 V, 30% Duty Cycle 110 A at 14.4 V, 100% Duty Cycle |

240V |

10 kVA | Repair and Maintenance, Stainless Steel Fabrication, Motor Sport Fabrication, Food and Wine | ||

| Weldarc 200AC/DC |

|

|

|

|

|

|

|

Steel, Stainless Steel, Copper, Aluminium, Titanium |

200 A at 18 V, 30% Duty Cycle 110 A at 14.4 V, 100% Duty Cycle |

240V |

10 kVA | Repair and Maintenance, Aluminium Boat Fabrication, Motor Sport Fabrication | |

| Maxstar 210DX |

|

|

|

|

|

|

Steel, Stainless Steel, Copper, Titanium |

210 A at 28.4 V, 30% Duty Cycle 125 A at 25 V, 100% Duty Cycle |

Autoline 210-480 V 50/60Hz Single or Three Phase |

7.4 kVA | Sheet Metal, Marine, Site Welding, Maintenance, Stainless Steel | ||

| Maxstar 400 |

|

|

|

|

|

|

Steel, Stainless Steel, Copper, Titanium |

400 A at 36 V, 20% Duty Cycle 300 A at 32 V, 60% Duty Cycle 250 A at 30 V, 100% Duty Cycle |

Autoline 210-480 V 50/60Hz Single or Three Phase |

12 kVA | Precision Metal Fabrication, Tube Mills, Pipe and Tube Fabrication, Tool and Die, Exotic Material Fabrication, Pressure Vessel Fabrication | ||

| Dynasty 210 |

|

|

|

|

|

|

|

Steel, Aluminium, Stainless Steel, Copper, Titanium |

210 A at 18.4 V, 60% Duty Cycle 175A at 17 V, 100% Duty Cycle |

Autoline 210-480 V 50/60Hz Single or Three Phase |

9.0 kVA | Precision Fabrication, Pipe and Tube Fabrication, Heavy Fabrication, Anodized Aluminium Fabrication, Aluminium Ship Repair, Aerospace | |

| Dynasty 300 |

|

|

|

|

|

|

|

Steel, Aluminium, Stainless Steel, Copper, Titanium |

250 A at 30 V, 40% Duty Cycle |

Autoline 208-600 V 50/60Hz Single or Three Phase |

12.5 kVA | Precision Fabrication, Pipe and Tube Fabrication, Heavy Fabrication, Anodized Aluminium Fabrication, Aluminium Ship Repair, Aerospace | |

| Dynasty 400 |

|

|

|

|

|

|

|

Steel, Aluminium, Stainless |

400 A at 36 V, 20% Duty Cycle

|

Autoline 210-480 V 50/60Hz Single or Three Phase |

19.4 kVA | Sheet Metal, Marine, Site Welding, Repair Maintenance, Aluminium Fabrication, Marine Fabrication | |

|

Capability |

|||||||||||||

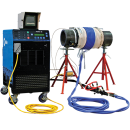

WIA offers a range of high quality Miller Arc welders and TIG welders.

The Miller Dynasty TIG welder range consists of the Dynasty 210DX, Maxstar 210DX and the Dynasty 400. Miller TIG welders provide advanced AC TIG technology for aluminium, increased productivity, improved weld quality, reduced energy costs and greater portability and space savings.

The Miller range of TIG welders are used by the best, including Triple Eight Race Engineering, the team behind the winning combination of Craig Lowndes and Jamie Whincup. Miller TIG welders are trusted for the fabrication of the roll cages and associated components in both Red Bull cars. The fact that the Triple Eight team trust the performance and precision of the Miller TIG welders to build one of the most critical components of the car when it comes to driver safety is certainly testament to their quality.

When it comes to TIG welding and Arc welding (also known known as stick welding), WIA has a wide range of welding machines and welding equipment that will assist with a range of different welding processes. The WIA range of TIG welders all feature inverter technology for greater portability for onsite applications. More information on our Inverter welders can be found here.

To assist in your decision on whether to use an Arc/TIG welder or a MIG welder, WIA has a handy equipment selection chart to assist you. Using the TIG and Arc welding process requires stick electrodes or tungsten electrodes instead of the welding wires that MIG welding requires. TIG/Arc welders don’t require a wire feeder and therefore make them a much more compact welding solution, and perfect for a wide range of applications. Included in the WIA range of Arc & TIG welders is the Weldarc 200i AC/DC machine which is capable of AC TIG and DC TIG welding which allows it to weld a wider range of steels including, stainless steel, copper, copper alloys, titanium and aluminium.

Not all welders are the same. While MIG welding machines use welding wires, TIG welding machines use tungsten electrodes and Arc welding machines use arc electrodes.

When welding, the application and materials to be welded should determine which is the most suitable welding machine.

All WIA and Miller Arc & TIG machines are capable of both Arc welding and TIG welding processes. To give you a better understanding of each process and their capabilities, we have put together a comparison of the Arc & TIG processes and what are the most suitable metals that can be welded:

Stick Welding

- Better suited for outdoors

- Best choice for quick repairs

- Easy to set-up as uses stick electrode instead of wire; often the beginner’s choice

- More lenient when it comes to welding dirty or rusty metal

- Effective on thick materials

Metals that can be welded:

Steel, stainless steel, mild steel and cast iron

Clean up:

After stick welding it is important to use either hand tools or power tools to remove any spatter to give accomplish a neat and tidy finish.

TIG Welding

- Provides precise, high-quality welds

- Preferred for architectural or automotive welding work

- Aesthetic-driven weld beads – achieves seamless look

- Allows heat input adjustment with a foot control

- Hardest welding process to learn

Metals that can be welded:

Steel, Stainless steel, aluminium alloys, chromoly, copper, brass and exotic metals such as titanium and magnesium