MIG Welders

WIA offers a complete range of high quality and reliable transformer and inverter MIG welders.

Weldmatic MIG Welders

Our customers have asked for it and we’ve delivered. WIA have recently added inverter MIG welder machines to their range of MIG welders. The range now includes the single phase Weldmatic 200i and Weldmatic 250i along with the three phase Weldmatic 350i and Weldmatic 500i. Portable and easy to transport from job to job, these machines are cost effective and contribute to a more productive workplace.

Reliable and high performing, the inverter MIG welding solutions are suitable for MIG, Stick and Lift Arc TIG welding and feature a built in thermal device that will cut in if the machine is operated beyond its safe thermal operating zone. In addition, the WIA inverter MIG welding machines suit shielded and flux-cored wires and come with built in VRD which delivers added safety when operating in Stick or Lift-TIG mode.

Fully compliant to Australian standards AS60974.1 and AS1674.2 CAT 2, WIA’s Inverter MIG welders are suitable for various applications, including rural jobs, construction sites, automotive panel repair and exhaust repair.

A stand out to the range is the Weldmatic 200i inverter MIG welder machine. This 200 Amp single phase welder has 200 Amps of MIG and 170 Amps of TIG capability. At only 13kg, the Weldamtic 200i is lightweight and portable, making it suitable for onsite maintenance.

Easy to set up and adjust the control panel allows easy selection for gas and wire type, with infinitely variable voltage and wire speed indicated on the digital display. A suggested setting chart allows the Weldmatic 200i to be set up quickly and easily.

All of WIA's inverter MIG welder machines are supported by an Australia wide service network, so you can be guaranteed you’re buying reliability and performance.

Single phase inverters are backed with a two year unlimited warranty, covering parts and labour (power source only). This includes the Weldmatic 200i and Weldmatic 250i. The Weldmatic 350i and Weldmatic 500i have an extra one year warranty, bringing the total to 3 years which also covers parts and labour.

WIA really does set the standard for inverter MIG TIG welders. At WIA we specialise in inverter MIG TIG and Stick welders all which have lift TIG capabilities. We also offer a wide range of other welding solutions including wire feeders and welding accessories.

Transformer MIG Welder Solutions

In addition to the inverter MIG welder range, WIA have a range of transformer MIG welder solutions.

Designed for the diverse range of Australian conditions, WIA’s transformer MIG welders can withstand the toughest of conditions, including high operating temperatures, high humidity, and dry and dusty environments. Every Weldmatic transformer MIG machine has quick and easy gun cable connection, fan on demand cooling, an easy screw spool hub, a heavy duty transformer, dual front handles, and is suited to both gas shielded solid wires and gasless (self-shielded) flux-cored wires.

With dual front handles, the Weldmatic transformers are easy to move around the workshop, plus they provide handy storage for interconnecting work leads. The tool tray is handy too, it provides storage for gun contact tips and nozzles.

With superior inductance technology, Weldmatic transformer machines have been engineered to deliver smooth arc performance right across the welding range. The package comes with the feature packed 4rd wirefeeder, which enables custom set up to suit the job – including arc start, low wire speed, burnback, spot time trigger latch, inch purge, and pre and post gas.

Rugged and Reliable, this compact MIG has the power to comfortably run all popular sizes of solid and flux cored wires and accommodates 5kg and 15kg spools – meaning greater flexibility across a range of applications.

Setting the industry standard for over 30 years, the Weldmatic Fabricator is the complete industrial welding MIG solution that has performance and reliability that is second to none. Suitable for medium to heavy applications including vehicle manufacture, ship building aluminium, stainless steel construction and the full range of steel fabrication, the Weldmatic Fabricator is a reliable choice.

WIA’s complete transformer MIG welder range includes single phase options including the Weldmatic 270 and Weldmatic 270C, as well as 3 phase options including the Weldmatic 356, Weldmatic 396 and the Weldmatic Fabricator.

Built to perform – Weldmatic is known for its extreme reliability and professional performance. From heavy duty drive systems to the industrial quality guns, every component is selected and engineered to ensure each Weldmatic machine performs. You can be guaranteed you’re buying reliability, because every WIA transformer MIG welder is backed by WIA’s industry leading ‘Gold Shield 3 Year Warranty’, covering parts and labour, and is supported by an Australia wide service network.

In addition, all WIA MIG welders undergo a series of stringent tests before ever leaving the factory, ensuring that every WIA MIG welder delivers on both reliability and durability. With a history of over 50 years in the Australian market, WIA’s MIG welders can be trusted to be the reliable choice and get the job done.

Miller MIG Welders

High quality and reliable Miller’s range of industrial MIG welders are designed to handle the most demanding industrial applications from construction, shipbuilding, fabrication, mining and maintenance. Each Miller MIG machine offers a range of suitable applications from MIG, Stick, and Pulsed MIG to Air carbon arc cutting and gouging.

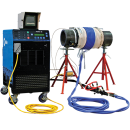

Included in the Miller MIG welder equipment range is the Deltaweld 602, XMT 350, XMT 350MPa, XMT 450, XMT 450MPa, Dimension 562, Dimension 812, PipeWorx Welding System and the PipeWorx 350 FieldPro

Suitable for MIG, Pulsed MIG, Stick, TIG and Flux-cored processes is the Miller XMT range. Each XMT machine offers pulsed MIG capability and optional optima control which reduces spatter and distortion, allows better out-of-position puddle control, and provides potential reduction of fume particle emission. In addition, the XMT 350, XMT 350 MPa, XMT 450 and the XMT 450 MPa features the fan on demand cooling system which operates only when needed, reducing noise, energy use and the amount of contaminants pulled through the machine. The XMT range also features Lift-Arc capability, which allows TIG starting without the use of high frequency and also starts the arc without contaminating the weld with tungsten.

Miller also offers MIG welders suitable for pipe welding, such as the PipeWorx Field Pro Welding System. With best in class productivity this system can boost productivity, reduce downtime and cut re-work. Easy to use the PipeWorx 350 FieldPro is streamlined and simplified to reduce set up time and potential weld defects. An addition to the 350 FieldPro is the remote control which provides the same functionality of the PipeWorx, hundreds of feet away from the power source, including process changeover and amperage adjustment with no special cables.

Some real features of this machine are the arc performance which has been optimised for critical pipe welding:

- Industry-leading arc performance like the PipeWorx 400 Welding System, but in a field-ready package.

- True multi-process system provides conventional Stick, TIG, FCAW, and MIG welding as well as the advanced technologies of RMD and Pulse.

- Smart Feeder delivers excellent RMD and Pulse welding up to 60 metres away from the power source with no control cables.

- RMD and Pulse processes also help reduce weld failures and eliminate backing gas on some stainless and chromoly applications.

Like all Miller machines the PipeWorx 350 FieldPro comes with 3 years’ warranty.

All Miller MIG welders undergo stringent quality testing before ever leaving the factory, ensuring that every Miller industrial MIG welder delivers on both reliability and durability.

For pricing, more information or to find your nearest WIA or Miller stockist, contact our customer support team on 1300 300 884.