Welded into Australia’s industrial history: A Q&A with WIA’s GM

Alan Hamilton has been at the helm of the Welding Industries of Australia (WIA) for almost 20 years.

As the Australian welding manufacturer and supplier celebrates its 60th birthday, Alan reflects on the reasons the company has achieved success in a highly competitive landscape whilst remaining true to its slogan: Trusted by the best.

Can you provide a history of WIA?

Welding Industries of Australia (WIA) started in Melbourne, 1962. The founders had worked with other welding supply businesses but felt there were some gaps in the market – they had a good understanding of what products were needed in Australia. WIA originally sold welding electrodes which suited the Australian market to a tee. Back then, power supply was poor, particularly in rural areas. The electrodes we sold were suited to the variable power supply that was common in rural markets at that time. So that’s how WIA began, filling a need for a welding solution in rural markets.

We then built on our product range, established an equipment plant in Adelaide and became recognised as a supplier of reliable, high quality welding products. In the 1980s and 1990s we manufactured many welding products, including one of the world’s first pulse MIG welders, the Weldmatic CDT.

In 2000, we became part of the Illinois Tools Works (ITW) group, and this enabled WIA to leverage the ITW Welding Platform resources and provide local industry with some of the top global welding brands including Miller, Hobart and Bernard in addition to our own locally produced WIA equipment range. A big advantage for our customers is that because we have this direct line to ITW Welding manufacturers we have been able to influence product development of key products for the Australian markets, including performance, safety, standards compliance, and regulatory requirements.

How has the business evolved over time?

Our reputation for supplying ‘good gear’ has remained unchanged, however, our product portfolio and sales strategy has evolved significantly over recent years.

We have optimised our product range and our focus to target market segments such as mining and infrastructure, whilst supporting our extensive distribution network. We’ve built on our reputation for being a trusted manufacturer and supplier by providing specialised welding solutions and advice from technical professionals who are respected by industry.

Who are WIA’s end users and key target markets?

The engineering and fabrication landscape has changed significantly over the last 25 years and companies such as WIA have needed to evolve to the changing needs of our target markets, whether they be commercial or industrial supply businesses or heavy engineering and mining services.

As we don’t sell products directly to end users, we work closely with our distribution partners to ensure our end users have access to our core products, as well as the expertise and technical support of our people.

What is WIA’s point of difference?

We care about customers, and we make the right decisions based on customer needs. That feeds into our sales strategy and how we work with our distribution channels to cater to our end users.

Another primary point of difference is the people we have on board to support our sales objectives. Our sales teams include highly trained and experienced fabrication people – hosting workshops to our key end user demographics. They have the technical knowledge and practical skills to engage with our end users and add value by going through best practices and features that can ensure their success.

Everyone in WIA – whether they are customer facing or not – is given the opportunity to grow, and that translates into mutual respect for each other and a common goal to provide our customers with the best products and the best customer experience.

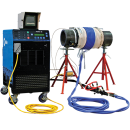

WIA’s stable of global ITW brands is truly market leading, Miller equipment is a major point of difference in heavy industrial applications where quality, reliability, efficiency and fitness for purpose is key to our customer’s success.

What is unique about the brands in your portfolio?

They are all unique in that they work very well for what they’re made for and are reliable. Our slogan, trusted by the best, isn’t just words, it’s true. WIA as a brand itself is highly trusted. As I’ve said earlier, Miller machines are renowned as among the best in the world and they are used by the major mining companies around the globe. For that reason, and because of our direct relationship with the Miller product development team over in the US, we can ensure these are built to the exacting safety standards and specs required by these miners in Australia.

Likewise, Hobart wires and Bernard MIG guns are high quality products and having these brings value to our customers who need dependability on weld outcomes and durability of guns and spares.

What would you say the primary challenges facing your customers are? How does WIA help address these?

Supply chain constraints seem to have posed the biggest challenge for our customers in terms of the wait times for manufactured equipment in the past two years. This has impacted shipping availability, lead times and associated costs along the supply chain.

We’re in a fortunate position as being part of the ITW family that we’ve been able to secure more inventory (where possible) to have on hand in Australia. We also take a very honest and transparent approach with our customers – communication is paramount. We discuss their delivery expectations and what we can do, or are doing, openly.

You’ve been with WIA for over 30 years. Can you tell us about yourself and that journey?

Coming from a trade background I joined WIA to try something a little different that was aligned to my background. Starting as a technical sales representative in Brisbane I quickly resonated with my customers, many of whom I remember fondly as I learned “how to sell”.

Over the following years I progressed to export, state and national leadership roles all of which were accompanied by quite steep learning curves, and I must acknowledge the many leaders whom I worked with who provided the wise counsel and encouragement that enabled me to remain on a career path of growth.

The acquisition of WIA by ITW in 2000 provided opportunity for further growth and the ITW business model was a good fit for me and over the next 4 years I was actively involved in shaping WIA for the future.

In 2004 I was appointed to the role of General Manager for WIA and in 2013 this responsibility was increased to include the Oceania Region.

My greatest pride comes from the people I work with, many of whom joined the company in much junior roles to what they hold today, and through their own efforts, and providing a culture where personal and professional growth is encouraged and directly supported. This is what motivates me.

What would you say to anyone considering working for WIA?

We are a respectful company with a family-focussed culture where good people tend to stay and grow. We take our values of: Trust, Respect, Integrity, Simplicity and Shared Risk seriously, in tandem with being a diverse, equal opportunity employer. If you want to work in an environment where opportunities, whilst not always apparent in the first instance, will present, and if you show initiative and work to our values, you will be provided lots of opportunity to grow and work with a great bunch of people.