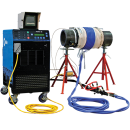

ArcReach® Technology

Improve safety, productivity & profitability

With ArcReach® technology, you can minimise the non-value added time spent walking to and from the power source and maximise arc on time, weld quality and job-site safety.

-

Easy adjustment

at the wirefeederWhen an ArcReach® accessory is connected to a compatible Miller power source, all control of that power source is transferred to the accessory. -

Fewer Cables

to MaintainOperators no longer need to trouble shoot welding system problems that results from damaged control cords. Plus, with ArcReach® control cords aren’t used, so associated costs are eliminated. -

Improved Job-Site

SafetyWith ArcReach® accessories less time will be spent walking to and from the power source, reducing slip, trip and fall hazards on the job-site. -

Better Welds With

Less Re-WorkOperators can now control and set the actual arc voltage and current delivered to the weld using the digital meters on the accessory. -

More Welds

in Less TimeOperators can now spend more time welding because weld settings can be adjusted at the ArcReach® wire feeder / remote rather than the power source. -

Cross Compatible

AccessoriesArcReach® accessories are compatible with Miller ArcReach® and non ArcReach® machines, however complete benefits are only realised with a full ArcReach® system.